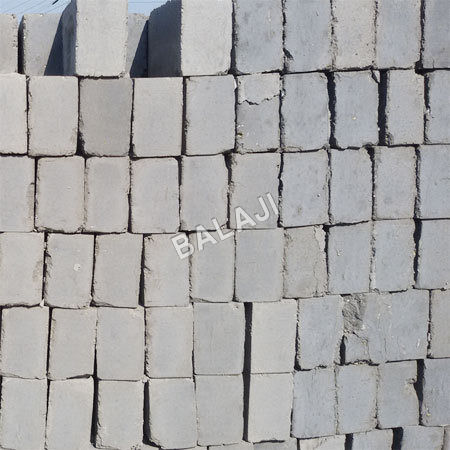

Construction Aggregates

Construction Aggregates Specification

- Working Life

- Long-lasting

- Compressive Strength

- High (1200-1600 kg/cm2)

- Dimension (L*W*H)

- Custom/Varies

- Drying Shrinkage

- Negligible

- Water Absorption

- 1% to 2%

- Porosity (%)

- 1-5%

- Material

- Stone Aggregate

- Type

- Construction Aggregates

- Color

- Gray

- Size

- Assorted (10 mm, 20 mm, 40 mm, etc.)

- Shape

- Angular

- Porosity

- Low

- Thickness

- Varies (typically 10 to 40 mm)

- Technics

- Crushed

- Feature

- High durability and strength

- Particle Size Distribution

- Well-graded

- Organic Impurities

- Nil or minimal

- Packing Type

- Loose or 50 kg bags

- Moisture Content

- <2%

- Specific Gravity

- 2.6 - 2.8

- Polishing Value

- Good (suitable for high-traffic applications)

- Application

- Road construction, civil engineering, ready-mix concrete, railways, drainage, landscaping

- Bulk Density

- 1520 - 1680 kg/m3

- Acid Solubility

- <2%

- Hardness

- Mohs scale 6-7

- Supply Capacity

- Bulk deliveries available

Construction Aggregates Trade Information

- Minimum Order Quantity

- 2000 Pieces

- Supply Ability

- 30000 Pieces Per Day

- Delivery Time

- 1 Days

About Construction Aggregates

Technical details:

|

Material |

Cement |

|

Size |

9 In. X 4 In. X 3 In. |

|

Brand |

A Garde |

|

For Use in |

Side Walls, Partition Walls |

|

Resistance Durability |

Fire Resistant |

|

Compressive Strength |

70-120 kg/cm2 |

Engineered for Diverse Construction Needs

These aggregates are essential in numerous construction sectors, from highways and bridges to drainage systems and landscaping. Their high durability, well-graded particle size distribution, and resistance to acids equip them for the rigors of heavy-duty locations, while their consistent particle sizes (10 mm, 20 mm, 40 mm, etc.) ensure versatile application in both large infrastructure and smaller scale projects.

Assured Quality and Reliable Supply

All aggregates are meticulously crushed and screened to deliver negligible organic impurities, excellent hardness (Mohs 6-7), and attractive low moisture content. With reliable bulk supply options and secure packaging, distributors, manufacturers, and suppliers in India can meet large project requirements on schedule, supporting seamless construction and engineering workflows.

FAQs of Construction Aggregates:

Q: How are construction aggregates classified for different construction applications?

A: Construction aggregates are classified based on properties such as size, shape, density, and hardness. For road construction and civil works, well-graded, angular aggregates in, for example, 20 mm or 40 mm sizes are preferred due to their superior compaction, high polishing value, and longevity in high-traffic situations. Fine grading is also crucial for ready-mix concrete and drainage.Q: What benefits do these aggregates offer for road construction and civil engineering projects?

A: Their high compressive strength (1200-1600 kg/cm), low porosity, and excellent durability make them ideal for load-bearing and high-traffic surfaces. They also maintain integrity under variable weather conditions and minimize maintenance needs, providing lasting performance in roads and civil structures.Q: When should well-graded aggregates be used instead of single-size aggregates?

A: Well-graded aggregates offer better compaction, stability, and reduced voids. They are especially suitable for applications like concrete production, road base layers, and railway ballast, where structural integrity and load distribution are critical. Single-size aggregates may be preferred for specialized drainage layers or decorative uses.Q: Where are these construction aggregates typically sourced and supplied from?

A: These aggregates are sourced from reputable quarries and processing units across India. As a leading manufacturer and distributor, we ensure bulk delivery or bagged supply to project sites nationwide, supporting contractors efficiently with consistent quality and timely logistics.Q: How is the moisture content in aggregates controlled during supply and storage?

A: Aggregates are processed to maintain moisture content below 2%, minimizing adverse effects on concrete mixes and construction quality. They are stored under controlled conditions to prevent water absorption, ensuring performance in ready-mix concrete and other sensitive applications.Q: What is the significance of the aggregates polishing value in high-traffic road applications?

A: A good polishing value ensures the aggregates resist becoming overly smooth under traffic, maintaining necessary surface texture for tire grip and road safety. This property is vital for highways and urban roadways experiencing frequent vehicular loads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Building Material Category

Construction Clay Bricks

Price Range 3.00 - 4.80 / Piece

Minimum Order Quantity : 2000 Pieces

Porosity : Other, Moderate

Shape : Rectangular

Size : 9 x 4 x 3 inches (approx.)

Material : Other, Natural clay

Construction Bricks

Price Range 3.00 - 4.80 INR / Piece

Minimum Order Quantity : 2000 Pieces

Porosity : Other, Medium

Shape : Rectangular

Size : 9 inch x 4 inch x 3 inch

Material : Clay

Industrial Fly Ash Brick

Price Range 3.00 - 4.80 / Piece

Minimum Order Quantity : 2000 Pieces

Porosity : Other, Low

Shape : Rectangular

Size : 230 mm x 110 mm x 100 mm

Material : Other, Fly Ash

Stone Dust

Price Range 3.00 - 4.80 INR / Piece

Minimum Order Quantity : 2000 Pieces

Porosity : Other, Low

Shape : Fine Powder/Granular

Size : Less than 5 mm

Material : Other, Stone

Gurgaon, Haryana, India

|

- Delhi NCR, Gurgaon

- Manesar, Bhiwadi, Jhajjar

- Rohtak, Rewari, Neemrana

- Other locations in Rajasthan & Haryana

|

BALAJI ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry